Classification:Product

Release time:2021-04-15

Number of visits:116

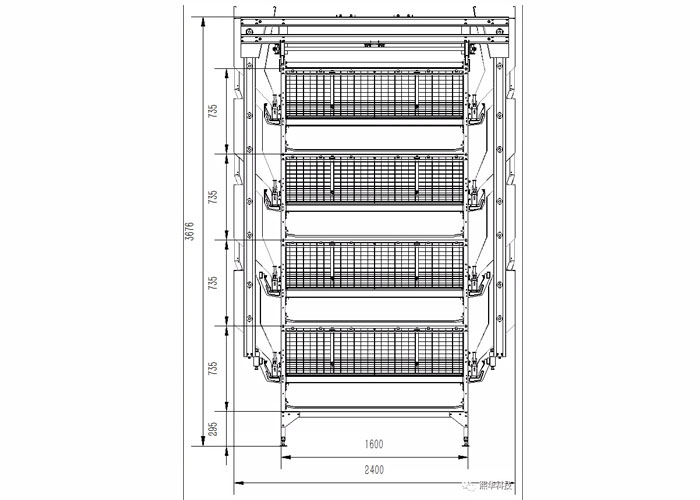

Overall advantages of travelling cage

When the density of cage feeding is large, the ventilation effect is ensured and the survival rate is improved

Pull type elastic floor design, fast chicken, avoid broiler injury

High strength galvanized wire and 275g / m2 galvanized sheet are more corrosion-resistant to ensure the service life of the main body

Special trough design, in line with the chicken feeding habits, uniform cloth, prevent loss

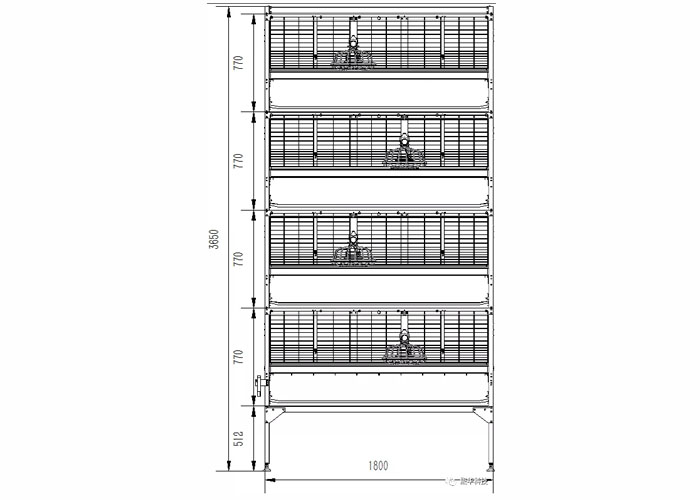

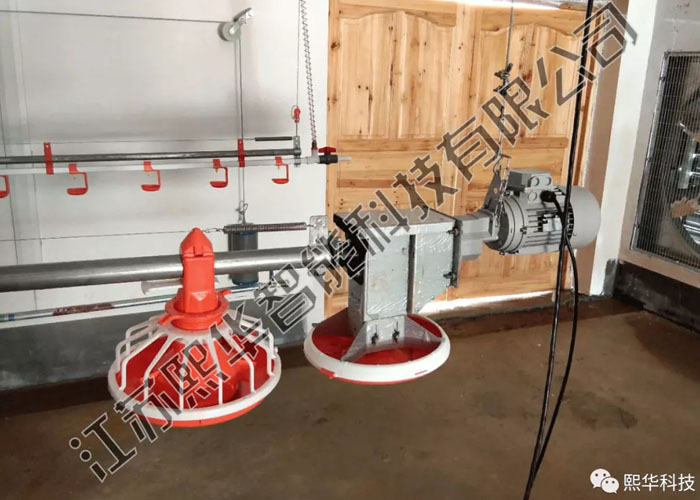

Overall advantages of disc cage

When the density of cage feeding is large, the ventilation effect is ensured and the survival rate is improved

Pull type elastic floor design, fast chicken, avoid broiler injury

High strength galvanized wire and 275g / m2 galvanized sheet are more corrosion-resistant to ensure the service life of the main body

Special feeding plate for broiler cage can realize automatic welfare feeding in the whole process and reduce feed waste

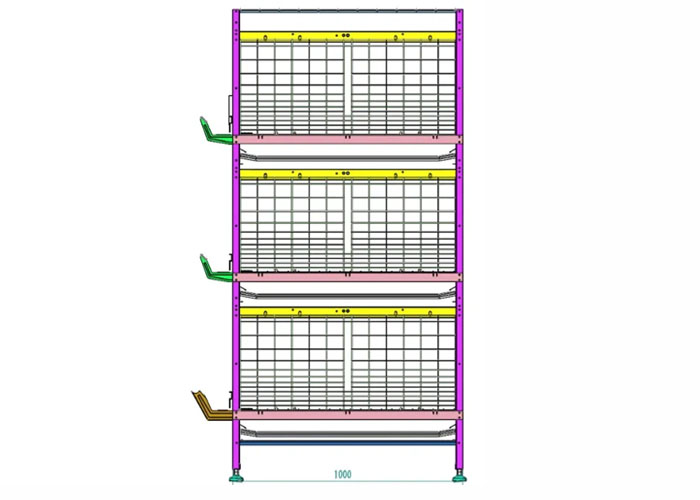

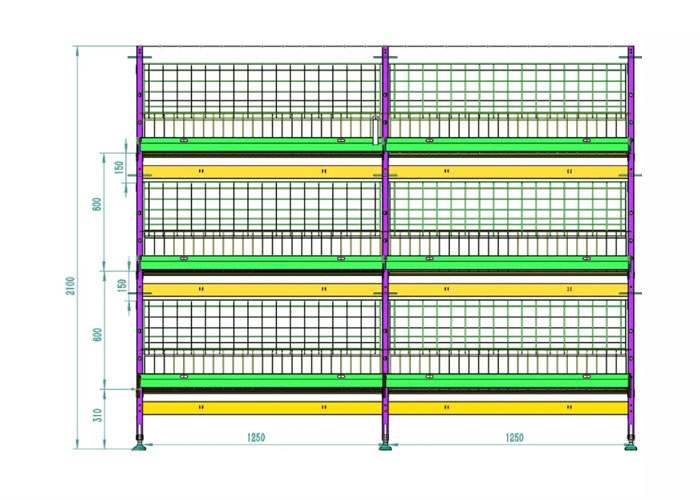

Overall advantages of single side seeding feeder cage

Galvanized sheet material, corrosion resistance; reasonable structure design, high strength, easy to use

The breeding height is 450mm and the floor height is 600mm, which is more conducive to the ventilation in the cage

Feed on one side and catch chicken on the other side to improve the efficiency of chicken production

The column frame has transverse hanging net beam and supporting net beam, which makes the column stand more stable

The bottom net can pass through the heating pipe, or the horizontal hanging net beam can pass through the heating pipe

The cage is made of stainless steel bolts, which is more resistant to corrosion and rust

| Travelling cage | 3 layers | 4th floor |

Chicken unit space(mm) | 1600×2400×460 | 1600×2400×460 |

| Unit feeding area(㎡) | 38400 | 38400 |

| Interlayer height(mm) | 735 | 735 |

| Cage height(mm) | 2941 | 3676 |

| Feeding amount of each group | 230 | 300 |

Note: the feeding density is 50kg / m2 (calculated according to 2.5kg / animal)

| Cage of material tray | 3 layers | 4th floor |

| Chicken unit space(mm) | 1800×3000×460 | 1800×3000×460 |

| Unit feeding area(㎡) | 54000 | 54000 |

| Interlayer height(mm) | 770 | 770 |

| Cage height(mm) | 2880 | 2880 |

| Feeding amount of each group | 320 | 430 |

Note: the feeding density is 50kg / m2 (calculated according to 2.5kg / animal)

| Cage parameters | 3 layers | 4th floor |

| Cage length(mm) | 1250 | 1250 |

| Cage depth(mm) | 1000 | 1000 |

| Cage height(mm) | 450 | 450 |

| Floor height(mm) | 600 | 600 |

| Cage height(mm) | 2100 | 2700 |

| Number of chickens per cage | 25 | 25 |

| Number of chickens per group | 75 | 100 |

Note: the feeding density is 50kg / m2 (calculated according to 2.5kg / animal)

Mailbox:1379999188@vip.163.com

Mailbox:1379999188@vip.163.com Telephone:+86 17351395583

Telephone:+86 17351395583 Address:No.8 Chuangye Road, environmental protection science and Technology Industrial Park, Yangzhou City, Jiangsu Province, China

Address:No.8 Chuangye Road, environmental protection science and Technology Industrial Park, Yangzhou City, Jiangsu Province, China WeChat official account

WeChat official account

Copyright ? 2021Jiangsu Xihua Intelligent Technology Co., Ltd Copyright

[蘇ICP備2021009177號(hào)] Website map XML長(zhǎng)夕網(wǎng)絡(luò)|Production and maintenance